Scalable and Flexible

Our solutions are as individual as your specific requirements for industrial printing and marking processes.

Automated Marking Systems

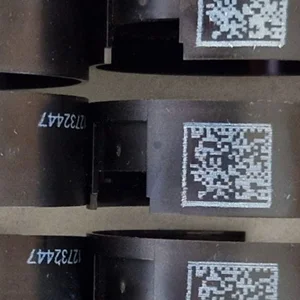

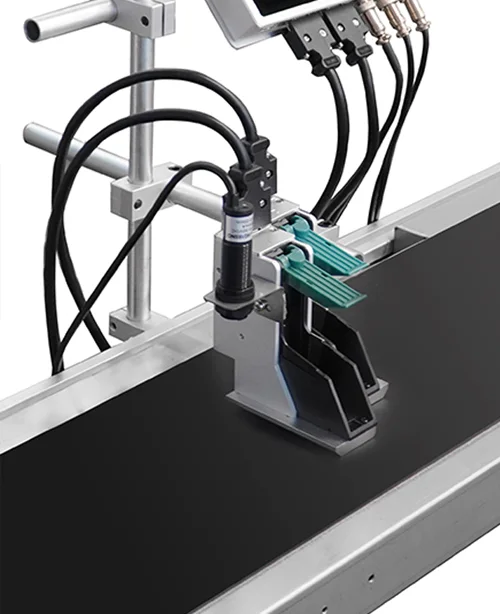

Modern production lines require reliable, flexible and traceable product marking. We integrate TIJ printers, sensors, trigger technology and software solutions directly into your production processes – providing precise print results with maximum efficiency.

Industrial printing and product marking play a central role in modern production processes. With precise, high-quality printing solutions, products can be reliably marked – from batch numbers and expiry dates to barcodes and logos. Modern marking systems such as inkjet, laser or thermal transfer printers provide fast, flexible and durable markings on almost any material.

Companies benefit not only from high production reliability but also from clear traceability and a professional brand appearance. Efficient product marking is therefore a key factor for quality, compliance and competitiveness.

Typical Use Cases

Modern marking systems can do more – and today, they also must do more. Even for small and medium-sized producers, time and cost-effectiveness play a major role in remaining competitive. Half-hearted and incomplete solutions simply aren’t real solutions anymore.

Industry Examples

High-quality and cost-efficient industrial printing is required today in almost all industries. Whether due to legal requirements, traceability needs or simple consumer information – dynamic printing processes for text, dates, barcodes or logos are needed everywhere that profit-oriented production takes place.

Integration, Safety & Interfaces

We view robots not in isolation, but as part of your overall system – including safety technology, operating concept and interfaces.

- Digital inputs/outputs for trigger, start/stop, status

- TCP/IP, serial communication, optional fieldbus

- API-based control for layout and data changes

- Connection to ERP/MES systems and SQL databases

- Vision systems for automatic code inspection

- Manual post-processing with handheld printers

- ...

From Idea to Finished Marking Solution

- Analysis: products, materials, print content, line speed

- Selection of suitable technologies (TIJ, piezo, laser, ...)

- Feasibility tests & trials using original materials

- Concept including hardware, software & integration plan

- Installation, parameterization & commissioning

- Training & long-term technical support