Cost-effective and flexible

Efficient mobile marking for modern production processes

TIJ Handheld Printers (Thermal Inkjet Hand Printers)

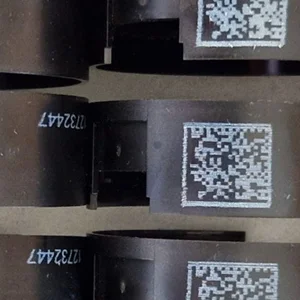

Industrial marking plays a central role in modern production and logistics processes. Whether best-before dates, batch numbers, barcodes, or logos – reliable and flexible printing solutions are essential. TIJ hand printers (Thermal Inkjet hand printers) have established themselves in recent years as a particularly practical and cost-effective solution. They combine mobility, high print quality, and ease of use, making them suitable for a wide range of industrial sectors.

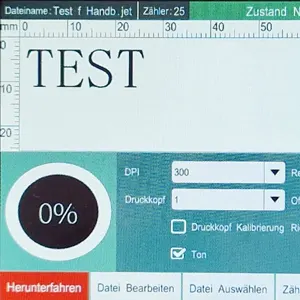

In TIJ printing, the ink is applied to the product through microscopic nozzles. A heating element briefly heats the ink, causing a droplet to be precisely ejected. The result is a sharp, high-resolution print with up to 600 dpi.

Typical applications of TIJ hand printers in industry

Thanks to their versatility, TIJ handheld printers are used in numerous industrial sectors:

Advantages of TIJ Handheld Printers Compared to Other Marking Systems

TIJ hand printers are a modern, flexible, and cost-effective solution for industrial marking. They are ideal for companies that want to print mobile, precise, and cost-efficiently – especially when handling variable data and smaller production runs.

Due to their high print quality, ease of use, and broad range of applications, TIJ hand printers have become an integral part of modern industrial processes.

Integration, Safety & Interfaces

We view handheld printers not in isolation, but as part of your overall system – including safety technology, operating concept and interfaces.

- Digital inputs/outputs for trigger, start/stop, status

- TCP/IP, serial communication, optional fieldbus

- API-based control for layout and data changes

- Connection to ERP/MES systems and SQL databases

- Vision systems for automatic code inspection

From Idea to Finished Marking Solution

- Analysis: products, materials, print content, line speed

- Selection of suitable technologies (TIJ, piezo, laser, ...)

- Feasibility tests & trials using original materials

- Concept including hardware, software & integration plan

- Installation, parameterization & commissioning

- Training & long-term technical support