Flexible Handling

Robots handle positioning, handling, and marking – precise and repeatable.

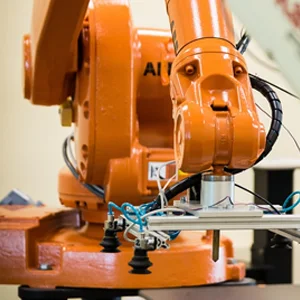

Robot-Guided Marking & Marking Cells

When components are variable, heavy, or hard to reach, traditional conveyor layouts reach their limits. Robots position TIJ printheads or products precisely – enabling flexible, compact, and future-proof marking solutions.

Typical Robotics Scenarios

Depending on the application, either the robot moves the printhead or positions the product correctly. In many projects, we combine robotics with vision systems and TIJ printers.

Practical Examples

Robotics shows its strengths wherever components need to be variable, heavy, or precisely positioned.

Integration, Safety & Operation

We view robots not in isolation but as part of your overall system – including safety technology, operating concepts, and interfaces.

- Selection of suitable robot types (articulated arm, SCARA, cobot)

- Grippers, tool changers, and fixtures for your components

- Integration of TIJ printers and vision systems into the cell

- Safety fences, scanners, light curtains, and enabling devices

- Support with risk assessment and CE compliance

From Idea to Robot Cell

- Concept Phase – Analysis of products, cycle times, space constraints, and interfaces.

- Feasibility Study & Simulation – Checking possible kinematics, reachability, and motion profiles.

- Detailed Planning & Design – Mechanical, electrical, and control engineering development of the cell.

- Assembly & Commissioning – Setup, programming, test runs, and handover to your production.

- Training & Support – Instruction of operating and maintenance staff and ongoing operational support.