Consulting, Solutions, Products

Product traceability is no longer an optional feature, but a decisive competitive advantage.

Complete Traceability

Product traceability has become a key element of modern production and supply chain processes. Companies are increasingly challenged to ensure full traceability of goods, comply with regulatory requirements, and optimize internal processes at the same time. One of the most cost-effective and flexible solutions is coding and marking systems based on TIJ marking machines (Thermal Inkjet) and handheld printers.

We explain in detail how product traceability works today, the advantages of TIJ technology, and why handheld printers are the ideal complement for flexible production environments.

What Does Product Traceability Mean?

Product traceability refers to the complete tracking of a product throughout the entire value chain – from raw material sourcing and production to delivery to the end customer. Key elements of product traceability include:

- Batch numbers

- Serial numbers

- Production dates

- Best-before dates

- Barcodes (1D/2D)

- QR codes / DataMatrix codes

This information is applied directly to products, packaging, or shipping cartons – often using modern coding and marking systems.

Why Is Product Traceability So Important?

1. Regulatory Requirements

In industries such as food, pharmaceuticals, cosmetics, and automotive manufacturing, traceability systems are legally required.

2. Quality Assurance

In the event of a complaint or product recall, affected batches can be quickly identified and withdrawn in a targeted manner.

3. Process Optimization

Transparent production data enables more precise analysis and continuous improvement of manufacturing processes.

4. Protection Against Counterfeiting

Serial numbers and unique codes make product counterfeiting significantly more difficult.

TIJ Marking Machines as a Key Technology

What Is TIJ (Thermal Inkjet)?

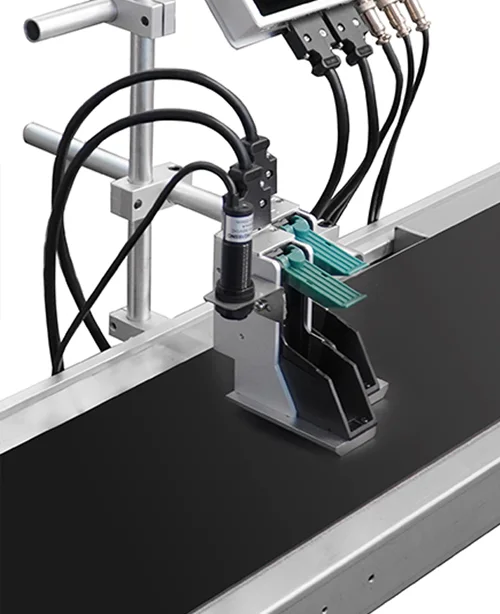

TIJ stands for Thermal Inkjet. This technology is based on precision ink cartridges that produce high-resolution prints without direct contact. TIJ marking machines are permanently integrated into production lines and are particularly suitable for:

- Corrugated boxes and cartons

- Labels

- Plastic packaging

- Metal surfaces (with specialty inks)

- Films and flexible packaging

- ...as well as wood, ceramics, and many other substrates

Advantages of TIJ for Product Traceability

1. High Print Resolution

TIJ systems deliver razor-sharp prints (up to 600 dpi). This is especially important for QR codes, DataMatrix codes, small fonts, and serialized numbering.

2. Low Maintenance and Clean Operation

As no external ink supply is required, complex cleaning procedures common with continuous inkjet systems are eliminated.

3. Flexible Integration

TIJ marking machines can be easily integrated into existing production lines and automated systems.

4. Real-Time Variable Data Printing

Through interfaces such as ERP or MES systems, variable data can be transferred directly from databases and printed in real time.

Handheld Printers for Mobile Marking

What Is TIJ (Thermal Inkjet)?

In addition to stationary TIJ marking machines, handheld TIJ printers offer significant advantages for flexible applications.

Typical applications in product traceability:

- Goods receiving

- Warehouse logistics

- Construction sites

- Small batch production

- Re-marking and rework processes

- Direct printing on shipping cartons

Advantages of Handheld Printers for Product Traceability

1. Mobility

Handheld printers are cordless and ideal for changing print positions and decentralized marking tasks.

2. Fast Implementation

No modification of the production line is required.

3. Individual Coding

Serial numbers, batch codes, date codes, and barcodes can be generated and printed directly on site.

4. Cost Efficiency

Particularly suitable for small and medium-sized enterprises (SMEs).

Product Traceability in Practice: Typical Workflow

- A production order is created in the ERP system

- A batch or serial number is generated

- The data is transferred to the TIJ marking machine

- The code is printed directly on the product or packaging

- The code is verified using a scanner

- The data is stored within the system

This closed-loop process ensures complete traceability.

The Future of Product Traceability: Industry 4.0 & Digitalization

With increasing digitalization, product traceability is becoming more automated. TIJ marking machines can be seamlessly integrated into:

- ERP systems

- MES systems

- Cloud solutions

- Database infrastructures

The combination of high-resolution coding and digital data storage enables full transparency across the entire supply chain.