Cost-effective and flexible

Efficient mobile marking for small to medium-sized batches

Efficient marking with modern handheld marking systems

In modern industry, logistics, and production, the marking of products, packaging, and components plays a central role. Whether batch numbers, best-before dates, barcodes, or logos – without reliable marking systems, seamless traceability is almost impossible. Handheld marking systems provide a flexible, mobile, and cost-efficient solution, especially for changing locations or small to medium batch sizes.

TIJ handheld printers (Thermal Inkjet) in particular have established themselves in recent years as a powerful and user-friendly technology.

TIJ stands for Thermal Inkjet, a printing technology in which ink is applied to the material through microscopically small nozzles using heat. This technology originally comes from the office environment but has been specifically developed for industrial applications.

In addition to TIJ, other technologies exist such as DOD (Drop on Demand), valve-based systems, or label printing.

Typical Applications of Handheld Marking Systems

Thanks to their versatility, handheld marking systems are used in a wide range of industrial sectors:

Advantages of TIJ Handheld Printers Compared to Other Handheld Marking Systems

TIJ handheld marking systems are used wherever mobile, flexible, and precise marking is required.

What to Consider When Purchasing a TIJ Handheld Marking System

When purchasing a TIJ handheld printer as a handheld marking system, several factors should be considered to ensure reliable and cost-effective marking over the long term. Print resolution and maximum print height play a central role, as they determine how detailed text, barcodes, or logos can be printed. A high resolution is particularly important for small fonts or 2D codes to ensure readability and scannability.

Equally important is selecting the right type of ink. Depending on the application and the material being printed, different ink types are required—for example, fast-drying inks for smooth surfaces, solvent-based inks for plastics, or specialty inks for metal and coated materials. Compatibility of the handheld marking system with multiple ink types significantly increases flexibility in daily use.

Another essential factor is the battery life of the TIJ handheld printer. Since handheld marking systems are often used in mobile and non-fixed work environments, the battery should provide sufficient operating time to cover longer shifts without interruption. In addition, ergonomics are important: lightweight construction, balanced design, and intuitive operation make the work easier and reduce strain on the operator.

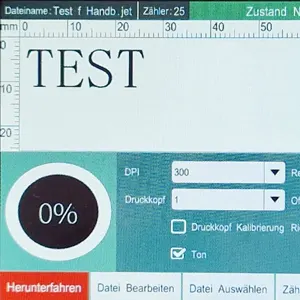

The software and user interface should also not be underestimated. A clear menu structure, easy text creation, and the ability to automatically generate variable data such as date, time, or sequential numbers contribute significantly to efficient operation. Modern TIJ handheld printers also offer interfaces for data transfer, which is particularly beneficial in industrial environments.

Last but not least, service, support, and availability of spare parts should be considered when making a purchase decision. A reliable manufacturer or supplier with fast support and long-term spare parts availability ensures that the handheld marking system can remain productive for many years.

Handheld Marking Systems with TIJ Technology in Industry 4.0

Thanks to interfaces such as USB and Wi-Fi, many TIJ handheld marking systems can be integrated into digital processes.

- Digital inputs/outputs for trigger, start/stop, and status

- TCP/IP, serial communication, optional fieldbus

- API-based control for layout and data changes

- Integration with ERP/MES systems and SQL databases

- Vision systems for automatic code verification

From Idea to Finished Marking Solution

- Analysis: products, materials, print content, line speed

- Selection of suitable technologies (TIJ, piezo, laser, ...)

- Feasibility tests & trials using original materials

- Concept including hardware, software & integration plan

- Installation, parameterization & commissioning

- Training & long-term technical support